Related Attributes

Product details

Glyceryl Monooleate Liquid, also known as Glyceryl Monooleate, is an organic raw material. Glyceryl Monooleate CAS 111-03-5 has the molecular formula C21H40O4 and molecular weight 356.5399. Glyceryl Monooleate Raw Materials are used as surfactants, lubricants, pharmaceutical raw materials, etc.

Functions of Glyceryl Monooleate Liquid

Glyceryl Monooleate Liquid is used as surfactant, lubricant, pharmaceutical raw material, etc

Applications of Glyceryl Monooleate Liquid

Daily chemical industry

As emulsifier, thickener and sunscreen, used in cream cosmetics and liquid washing shampoo

As fabric finishing agent and pigment grinding additive in textile industry

Medical field

Carrier of drug delivery system, combined with bile salts to promote drug absorption

Forming swelling phase for controlled release preparations, with biocompatibility

Food and industry

Food stabilizer (note to distinguish from xylitol anhydride monostearate)

Plastic/rubber additives and lubricants

Other functions

Antistatic agent (PE/PP/PVC materials) and defoaming agent

Product method of Glyceryl Monooleate Liquid

1. Direct esterification method

Glycerol and oleic acid are heated and reacted under the action of acidic (such as sulfuric acid, hydrochloric acid) or alkaline catalyst (such as sodium hydroxide) to produce a mixture of monoolein, diglycerol and by-products, which needs to be purified by molecular distillation

2. Hydroxyl functionalization derivatization method

Using monoolein as raw material, carboxylic acid groups are grafted with maleic anhydride through esterification reaction, and anionic surfactants can be further synthesized.

1. Solvent system optimization

Tertiary butanol system: Novozym 435 lipase catalysis, substrate molar ratio (glycerol: oleic acid) 1:3, 50℃ reaction for 8 hours, monoglyceride yield 71.35%.

Mixed solvent system: tertiary butanol/isopropanol (80/20, v/v) can reduce the melting point to 6.9℃, and the monoglyceride yield is increased to 75.31%.

2. Continuous production

The packed bed reactor (PBR) continuously catalyzes the glycerol hydrolysis of tea seed oil. When the feed rate is 0.25 mL/min, the monoglyceride content reaches 80.74% and the production capacity is 0.698 kg/(kg enzyme·h)

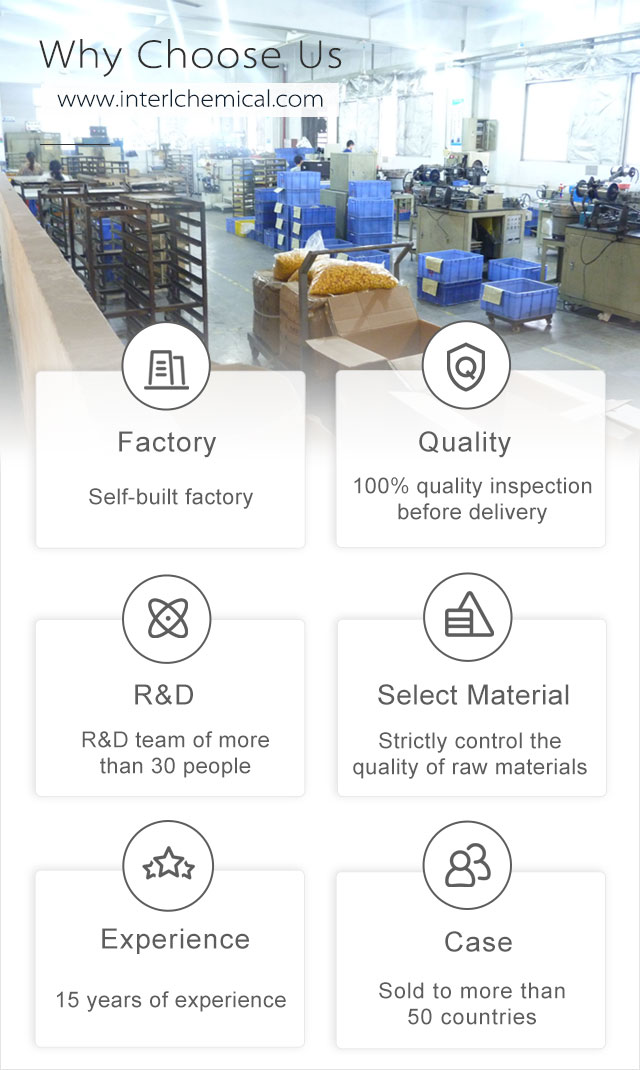

Why choose us?

HRK Factory

About Shipping

Pharmaceutical Intermediate manufacturers

©2023 Xi'an Henrikang Biotech Co., Ltd.,