Related Attributes

Product details

Polyacrylic acid powder, commonly known as plexiglass, is a polymerised polymer compound made from methyl methacrylate. The four commonly used synthesis methods are anionic polymerisation, solution polymerisation, polyacrylic acid CAS 9003-01-4 polymerisation and suspension polymerisation. In addition, polyacrylic acid Raw Materials have excellent properties such as easy colouring, light weight and unbreakable, and good processing performance.

Applications / Functions of polyacrylic acid powder

polyacrylic acid Raw Materials can be used as film-forming agent and binder in leather finishing agent, also used in making polyacrylic resin emulsion paint, etc.

polyacrylic acid powder is widely used in the decoration of light leather, such as face leather, garment leather, glove leather, etc. It can enhance the leather's bending resistance, extensibility, light resistance, aging resistance, cold resistance, heat resistance, and it is the main modifying film-forming agent for modifying grain leather with pigment paste.

Polyacrylic acid CAS 9003-01-4 is used in the manufacture of cosmetics, ointment can promote the absorption of grey and yellow mould, and can be used in the control of drug release.

Physicochemical Property of polyacrylic acid powder

Polyacrylic acid CAS 9003-01-4 is white powder. It is infinitely miscible with water.

Production methodprocess of polyacrylic acid powder

Add 530kg of deionised water into the polymerisation kettle, add 41kg of PINGPINGA OS-15 and stir to dissolve. Add 4kg of sodium dodecyl sulphate, stir to dissolve, then add 68kg of mixed monomer (butyl acrylate, acrylonitrile) within 20min.

After stirring for 15mi, add 30kg of 1.5% aqueous ammonium persulfate solution and finish within 30min. Continue stirring for 15min and then slowly increase the temperature to 70℃, start to add the mixed monomer (272kg) dropwise, about 1h dropwise finish. After the addition, it was kept at 80℃ and stirred for 1h.

After the reaction is completed, the temperature is lowered to about 40 ℃, add 70kg Pingpingga OS-15, stirring for 15min, filtering, remove impurities to get polyacrylic acid Raw Materials.

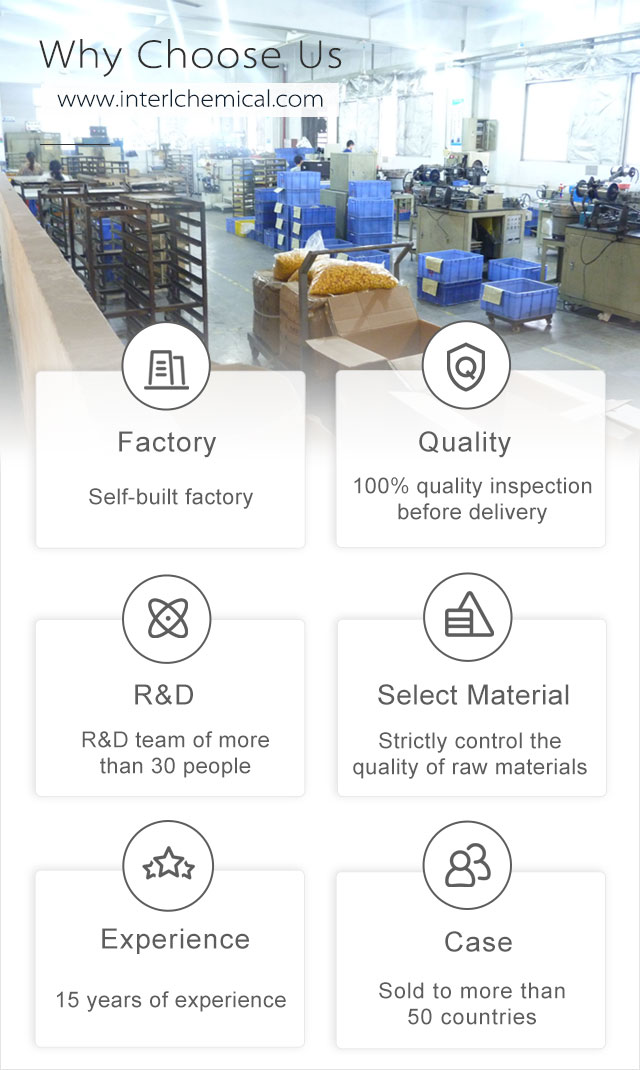

Why choose us?

HRK Factory

About Shipping

Pharmaceutical Intermediate manufacturers

©2023 Xi'an Henrikang Biotech Co., Ltd.,